CNC kugaya uye kutendeuka kune zvakasiyana-siyana, inodhura-inoshanda uye yakarurama, zvakadaro mikana yeCNC michina yezvikamu inowedzera kuwedzera kana mamwe mapeji achitariswa.Ndezvipi zvingasarudzwa?Kunyange zvazvo izvozvo zvichiita semubvunzo wakapfava, mhinduro yacho yakaoma kunzwisisa nokuti pane zvinhu zvakawanda zvokufunga nezvazvo.

Prototype Projects

Kutanga, kuguma ndekwechii?Iko kuvandudza aesthetics kana kuita?Kana iyo yekupedzisira, ndeapi maitiro ekuita anoda kuvandudzwa?Corrosion kuramba, kuoma kwepasi, kupfeka kuramba kana EMI/RFI kudzivirira?Iyi ingori mimwe yemibvunzo ichapindurwa saka, tichifunga kuti mugadziri anoziva zvinangwa, ngatitarisei pane dzakasiyana sarudzo.

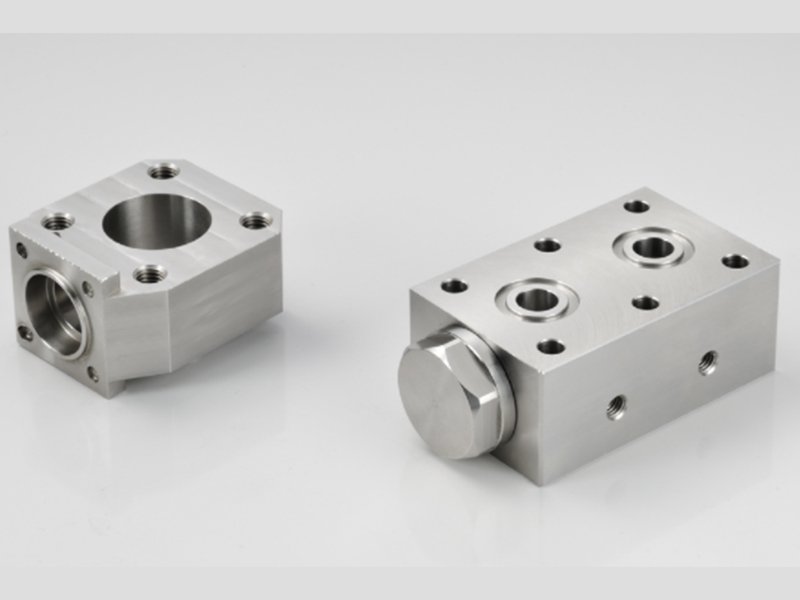

Inopedzisa yeCNC Yakagadzirwa Metal Prototype Zvikamu

Kwemakore makumi mana apfuura, maPrototype Projects 'machinist akakumbirwa kuti abudise zvikamu kubva kune yakakura yakawanda yesimbi yekushandiswa mumaindasitiri mazhinji.Zvigadzirwa zvinogara zvichibviswa, kucheneswa uye kuderedzwa, zvisinei, kusarudzwa kwekupedzisa kwakafara kwazvo.

Nhasi, simbi dzinonyanya kufarirwa nevatengi vedu ialuminium alloy 6068, simbi isina tsvina 304 uye simbi isina simbi 316. Chokwadi, matatu aya anogara achikumbirwa zvekuti tinobata masheya awo muhukuru hwakasiyana-siyana kuti tisangane nezvinodiwa zvemazuva matatu edu Express CNC. machining service.

Ichiri kufarirwa asi yakataurwa zvishoma kazhinji imhangura, ndarira, phosphor bronze, nyoro simbi, mudziyo simbi.Nguva nenguva, vatengi vanokumbira sepcial simbi.Kana tikakwanisa kuwana zvinhu uye nekuzvigadzira mumba, tichazviita, zvikasadaro tinowanzo bvumira basa kune nyanzvi yakasarudzwa kubva kunetiweki yedu yemashopu emuchina akavimbika.Semuenzaniso, alloys ekunze seInconel, Monel uye Hastelloy anowanzoda mamwe matekiniki uye maturusi, saka isu tinowanzo shandisa izvi.

Metal inogona kupedzwa nenzira dzakawanda dzakasiyana.Semuenzaniso, aruminiyamu inogona kazhinji kuve yakajeka anodised, hardcoat anodised, kana dema kana ruvara anodised.Sarudzo inoenderana nekuti chinodiwa ndechekuwedzera aesthetics kana kuita (kunyanya corrosive kuramba kana kupfeka kuramba).

Simbi isina simbi inoshingirira mukuora asi dzimwe nguva vatengi vanotsanangura mamwe mapeji.Electropolishing, semuenzaniso, inogadzira kupedzisa kwemhando yepamusoro pamwe nekubvisa uye kubvisa mipendero kubva kune dzakaoma kunzwisisa.Kune rimwe divi, kana kuoma kwepamusoro, kupfeka kuramba kana kuneta kuita kuchida kuvandudzwa, ese 304 uye 316 simbi isina tsvina inogona kuve nitrocarburised kana nitrided.

Simbi yakapfava inobatsira kubva pamwe sarudzo yakafararira yekupedzisa.Sarudzo dzinosanganisira pendi yakanyorova, pendi ye electrophoretic, poda coating, electroplating, makemikari madema, electropolishing, kuomesa, titanium nitriding (TiN) coating, nitrocarburising, uye kuputika bead, nezvimwe.

Mhangura nendarira zvinowanzotsanangurwa kune zvikamu zvinoshanda, pasina kumwe kupedzisa kunodiwa mushure mekugadzira.Kana zvichidikanwa, zvisinei, zvikamu zvinogona kukwenenzverwa nemaoko, electropolished, electroplated, vapor blasted, lacquered kana kurapwa nemakemikari blacking.

Mapedzisiro ataurwa pamusoro apa haasi iwo ega anowanikwa esimbi uye alloys.Isu tinogara tichifara kukurukura zvekupedzisa nevatengi uye tinoedza kubatsira chero kwatinogona.

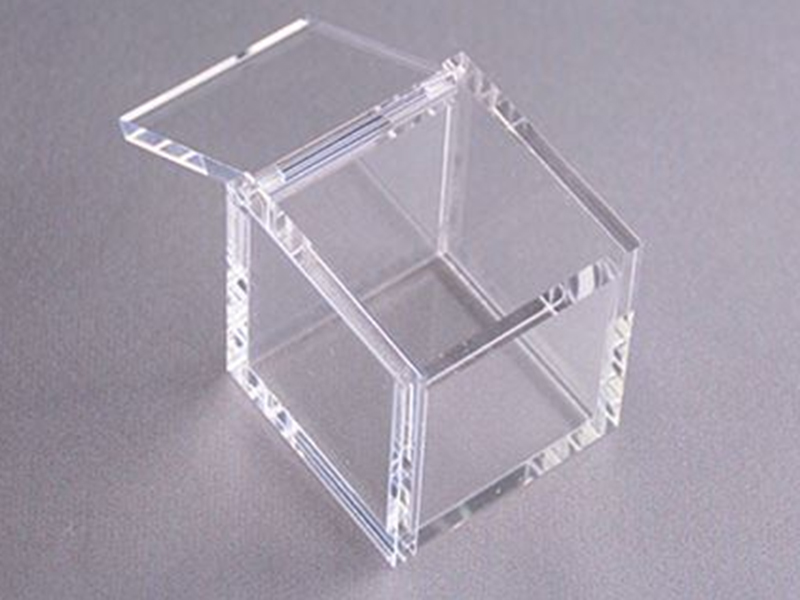

Inopedzisa yeCNC Yakagadzirwa Plastic Prototype Zvikamu

Sezvinoita simbi dzakapatsanurwa, ese epurasitiki zvikamu isu CNC muchina akanyanya kubviswa, kucheneswa uye kubviswa mafuta asi, mushure meizvozvo, sarudzo dzepamusoro dzinowanzove dzakasiyana.

Sezvo ruzhinji rwevatengi vanokumbira CNC yakagadzirwa prototype mapurasitiki zvikamu mune angave acetal (dema kana zvakasikwa) kana acrylic, isu tine marudzi ezvinhu zviri mustock.Acetal haigamuchire magumo ekuwedzera, saka zvikamu zvinowanzo kupihwa 'semuchina'.

Acrylic, kuva yakajeka, inowanzoputirwa kuti ionekwe pachena.Izvi zvinogona kuitwa nemawoko nemakiredhi akateedzana eabrasive, kana nekupenya kwemoto.Sekukumbira kwemunhu, acrylic inogona kupendwa ne acrylic pendi kana vacuum metallised kuti iwane yakanyanya kupenya.

Zvimwe zveizvi zviri nyore kupedza kupfuura zvimwe, saka unogamuchirwa nguva dzose kukurukura zvekushandisa uye kupedza nesu.Nezve mapurasitiki, tinogona jecha, prime uye pendi zvikamu, kupukuta (nemaoko kana nemurazvo), electroless ndiro kana vacuum metallise.Kune mamwe mapurasitiki ane yakaderera pamusoro pesimba, nyanzvi kugadzirira pamusoro neprimer kana plasma kurapwa kunodiwa.

Dimensional Kuongorora kweCNC Yakagadzirwa Prototype Zvikamu

Chimwe chikonzero nei vatengi vachisarudza kuve neprototype zvikamu CNC muchina pane 3D yakadhindwa ndiko kurongeka kwepamusoro.Kushivirira kwedu kwakatarwa kweCNC michini zvikamu ± 0.1mm, kunyange zvimiro zvinowanzobatwa kune zvakanyanya kushivirira, zvichizviisa pasi pechimiro, zvinhu, uye geometry.Isu tinonyatso ongorora zviyero, hongu, vatengi vanogona zvakare kukumbira chaiwo maficha akatariswa.

Kazhinji zviyero zvinogona kutorwa nemaoko anosheedzera callipers kana mamicrometer asi yedu co-ordinator yekuyeresa muchina (CMM) yakanakira kunyatsoongorora.Izvi zvinotora nguva uye hazviwanikwe neyedu yepamusoro CNC sevhisi asi inokurumidza kupfuura kutumira zvikamu kune wechitatu-bato kuti CMM iongororwe.Izvo chete zvinosarudzika ndezvekuti panodikanwa, yakazara-yakarongedzwa-yakazara CMM yekuongorora routine, kana batch rezvikamu rakagadzirwa uye 100 muzana yekuongorora inodiwa.

Sarudzo dzeGungano dzeCNC Machined Prototype Zvikamu

Chimwe chikonzero ndechekuti vatengi vanosarudza kuve neprototype zvikamu CNC muchina pane 3D yakadhindwa ndiko kurongeka kwepamusoro.Iyo inotenderwa kushivirira yeCNC michina zvikamu ndeye ± 0.1mm, kunyange zvimiro zvinowanzobatwa kune zvakanyanya kushivirira, zvichienderana nechinhu uye geometry.Tichanyatsoongorora zvikamu zvese tisati tatumirwa, uye vatengi vanogona zvakare kukumbira kuti chaiwo maficha atariswe zvakare.

Kazhinji zviyero zvinogona kutorwa nemaoko anosheedzera callipers kana mamicrometer asi yedu co-ordinator yekuyeresa muchina (CMM) yakanakira kunyatsoongorora.Inokurumidza kupfuura kutumira zvikamu kune wechitatu-bato kuti CMM iongororwe.Izvo chete zvinosarudzika ndezvekuti panodikanwa, yakazara-yakarongedzwa-yakazara CMM yekuongorora routine, kana batch rezvikamu rakagadzirwa uye 100 muzana yekuongorora inodiwa.

Nguva yekutumira: Jun-30-2022