Kune zviuru zvezvigadzirwa mumusika, asi unoziva here kusarudza kwakakodzera zvinhu?Uye unoziva here nzira yekuwana yakanakisa zvinhu kune yakoCNC prototype zvikamu?Kana uri panguva yakaoma kudai,

iwe uchawana kusarudza yakakodzera zvinhu zvechigadzirwa chako zvinorambidzwa nezvakawanda zvinhu.Nheyo yakakosha inofanirwa kuteverwa ndeye: kuita kwechinyorwa kunofanirwa kusangana neakasiyana hunyanzvi zvinodiwa uye zvakatipoteredza zvinodiwa zvechigadzirwa.

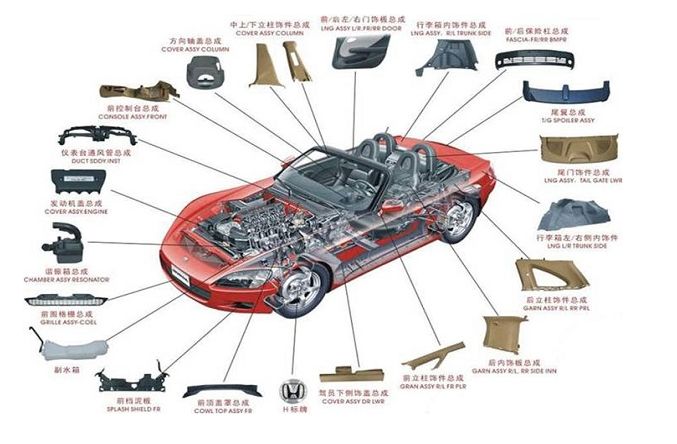

Paunenge uchisarudza zvinhu zvemechani zvikamu,CNC Prototyping Zvikamu, Kurumidza Prototyping, Hardware Prototyping, nyowani simba mota, unogona kutarisa zvinotevera zvinhu zvina:

1)Kuoma kwezvinhu

Rigidity ndiyo inonyanya kutariswa pakusarudza zvinhu, nekuti iwo chaiwo zvikamu zvinoda kugadzikana uye kupfeka kuramba mukuita basa rinoshanda, uye kuomarara kwezvinhu zvinotaridza kugona kwekugadzirwa kwechigadzirwa.Kuwedzera kuomarara kunoreva kuti zvinhu zvacho hazvigone kutsvedza pasi pesimba rekunze.Zvinoenderana nehunhu hweindasitiri, #45 simbi uye aruminiyamu alloy inowanzosarudzwa kune isiri-yakajairwa tooling magadzirirwo;#45 simbi uye aruminiyamu alloy anoshandiswawo zvakanyanyacustom parts machining;aluminium alloy inonyanya kushandiswaAutomotive Prototype magadzirirwo.

2)Kugadzikana kwezvinhu

Nokuda kwechigadzirwa chine zvakakwirira chaizvo zvinodiwa, kana isina kugadzikana zvakakwana, iyo yakasiyana-siyana deformation ichaitika mushure megungano, kana kukanganiswa zvakare mukugadzirisa kushandiswa.Muchidimbu, nekuchinja kwekushisa, humidity uye vibration uye imwe nharaunda mune nguva dzose deformation, iyo inotyisa kune chigadzirwa.

3) Materials 'machinable

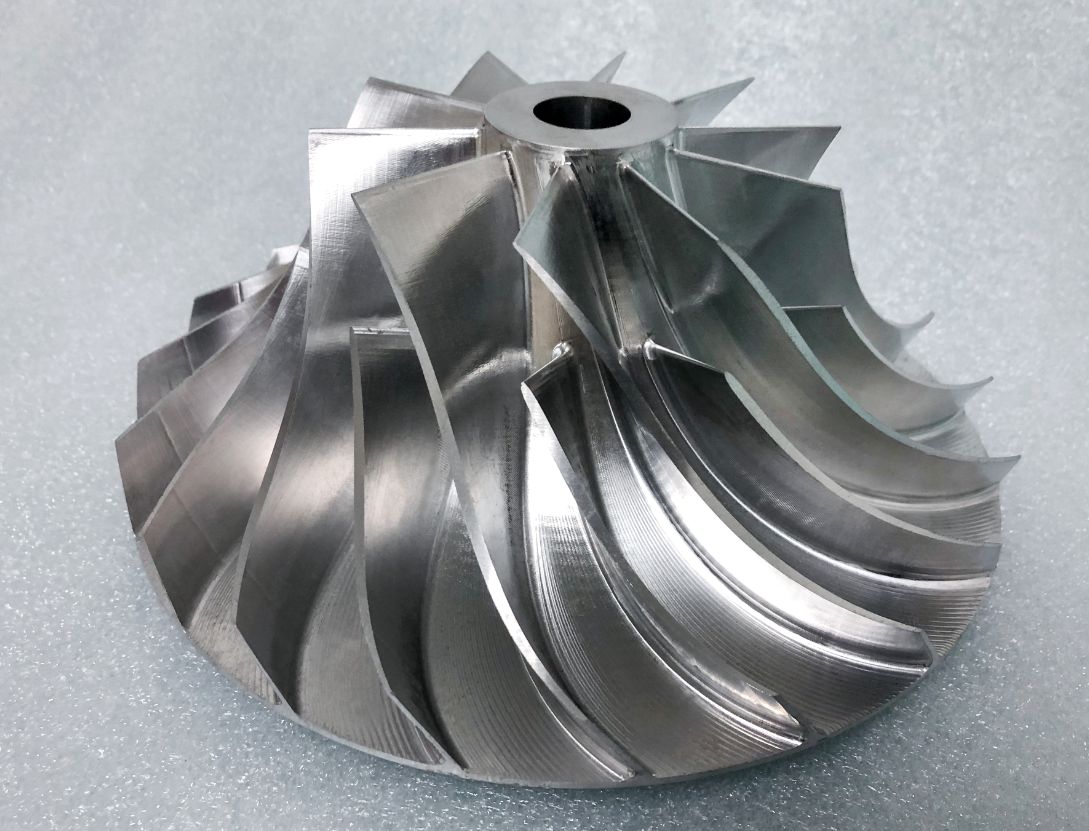

Iyo machining pfuma yezvinhu inosarudza kana chikamu chiri nyore kugadzira kana kwete.Kuenzaniswa nealuminium alloy prototype zvikamu,

simbi isina tsvina ine kuoma kwepamusoro uye yakanyanya kuoma kugadzirisa.Nekuti zviri nyore kukonzeresa kupfeka kwechishandiso panguva yekugadzirisa.Semuenzaniso, kugadzira mamwe maburi madiki muzvikamu zvesimbi zvisina tsvina, kunyanya maburi ane shinda, zviri nyore kutyora madhiri uye kucheka maturusi, zvakare nyore kutyora screw tap, izvo zvinozotungamira kune yakanyanya kudhura machining mutengo.

4) Mutengo wezvinhu

1.Mutengo chinhu chakakosha kufunga pakusarudza zvinhu.Mumamiriro ezvinhu ekukurumidza kukura kweAI tekinoroji uye inofarirwa simba idzva, maitiro ekusarudza akanakisa zvinhu kuchengetedza mutengo uye kuchengetedza nguva yekupinda mumusika inova inove maitiro!Semuyenzaniso, Titanium alloy ine huremu huremu, iyo yakakwira chaiyo simba uye yakanaka corrosion kuramba.Inoshandiswa zvakanyanya muinjini itsva yemotokari yemagetsimasystem uye anoita basa risingayerike mukuchengetedza simba uye kuderedza kushandiswa.Pasinei nepamusoro pezvinhu zvetitanium alloy zvikamu, chipingamupinyi chikuru chakakonzera kushandiswa kwayo kwakapararira muitsva energgy mota indasitirindiwo mutengo wakakwirira.Unogona kusarudza zvinhu zvakachipa kana usingadi kuva nazvo.

Zvinhu zvisiri izvo, zvese pasina!Ndapota chenjerera kusarudza zvinhu zvako, Kana iwe usingazivi nzira yekusarudza, tapota inzwa wakasununguka kutibata nesu, tiri paIndaneti nguva dzose, ndinokutendai!

Nguva yekutumira: Kubvumbi-20-2023