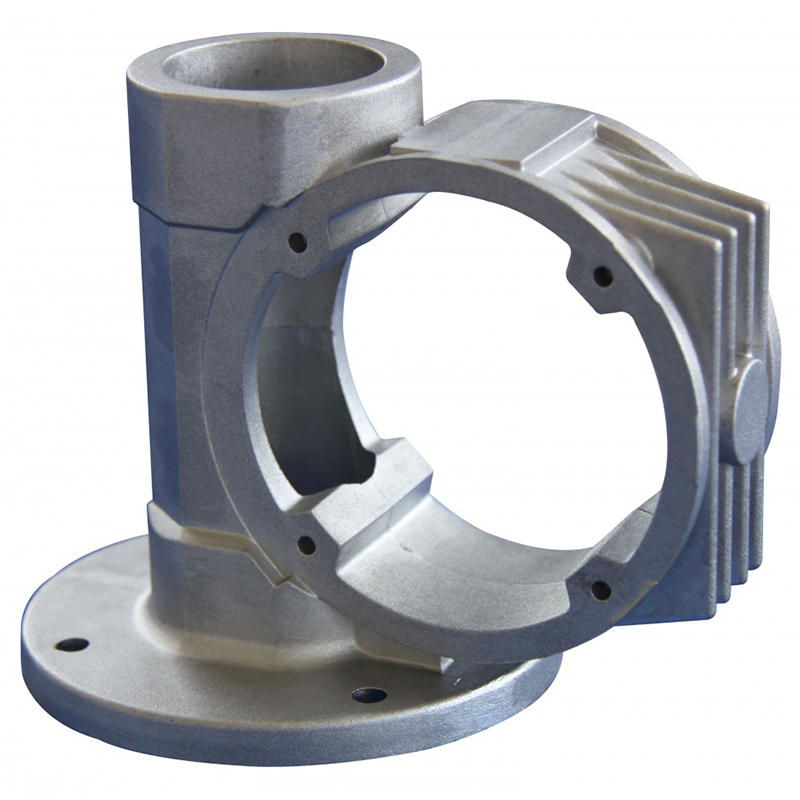

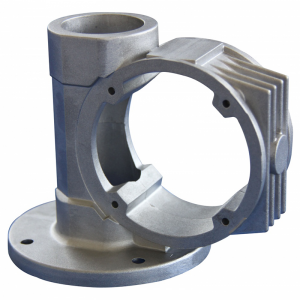

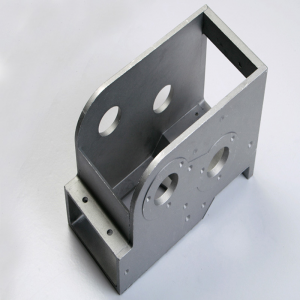

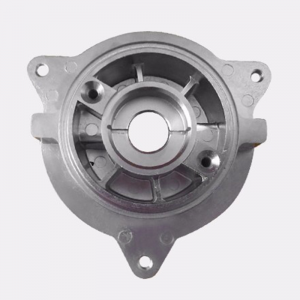

OEM Metal Die Casting Maitiro Sample Kugadzira

Details

| Item | Tsanangudzo |

| Process Technology | Kukanda wakisi yakarasika Iyo yakanyungudika yegirazi yekukanda maitiro Silica casting process Die casting process Jecha kukanda maitiro pamwe nePrecision CNC Machining Surface Treatment |

| Nyaya Inowanikwa | (1) grey iron, ductile iron, nguruve iron |

| (2) carbon simbi, Stainless simbi, alloy simbi | |

| (3) aluminium alloy, aruminiyamu, A380, aruminiyamu 6061 | |

| (4) zinc alloy, mhangura, ndarira, ndarira nezvimwe | |

| Weight Range | 0.02-50 KGS |

| MOQ | 500 Zvimedu |

| Kushivirira | ± 0.02mm |

| Testing | Matatu ekubatanidza kuyerwa muchina wekuyedza. |

| Certification | ISO9001:2015 |

| Standard | ISO, DIN, AISI, ASTM, BS, JIS, nezvimwe. |

OEM Material

Investment casting: ASTMA148-class80-40, ASTMA148-class80-50, A572GR60, AISI316, Stainless Steel, ST52, S355, GS-52.3, ASTMA48-class30B, CK45, 1.7218-25Cr

Kukandwa kwejecha:GGG50, GGG30, ASTMA48-class25B, 42CrMo4, C22, Ductile iron65-45-12, AlCuMgpbF34, EN-JIS-500-7, EN1563, EN10293-GE3000, DINT205CH205CH205CH205CH205CH205CH205CH205CH205CH205CH205CB205CH205CH205CH205CH205CH205CH205CH21GHT-7, EN-JIS-500-7

Die Casting:C1040, A356, A380, AISI12

Zvakanakira Metal Die Casting

1. Inogona kuita zvikamu zvesimbi nemhando dzakaoma, zvinyorwa zvakajeka, masvingo akaonda uye mazamu akadzika.

2. Die casting ine yakakwira dimensional kurongeka uye yakanaka kuchinjana.

3. Kubudirira kwekugadzirwa kwepamusoro uye kugadzirwa kwehuwandu.

4. Zviri nyore kushandisa zvimedu zvemosaic.

5. High material utility rate.

Zvigadzirwa zvikamu

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top